Agrico PSA first farm with fully compliant potato traceability

PSA FIRST FARM WITH FULLY COMPLIANT POTATO TRACEABILITY

PSA is the first farm in Kenya where the entire history of all of its produced potatoes is fully traceable now. This matters because modern retailers – such as KFC – often demand such traceability from its value chain partners, in order to comply to their food safety policy. PSA is the only organisation that offers the combination of modern potato varieties – grown in Kenya such as Markies – and a fully compliant potato traceability. This enables Kenyan potato processors to produce according to the high international standards and compete with imported French Fries. Potentially it can also unlock export markets for them. Naturally Kenyan farmers also benefit: we encourage them to implement our traceability system themselves, so they too can become ‘key players in the potato premier league’.

KFC French fries shortage: catalyst for potato traceability system

The foundation for PSA’s potato traceability was PSA’s existing farming management system that has been in place for many years. Some minor ‘management system tweaking’ was needed for it to become a fully compliant traceability system.

The situation with KFC became a catalyst to further improve our existing farming management system. KFC had been importing French fries due to the lack of Kenyan qualified supply. This became clear by the shortage of French fries in their Kenyan restaurants in the beginning of 2022, caused by disrupted supply chains. KFC decided to start sourcing its French fries from Kenya. Two main conditions for this strategic change were identified, namely using the right potato variety (Markies) and assuring Kenya’s compliance to its food safety standards.

PSA already matched the first condition: it had been growing the seed potato variety – Markies – for many years in Kenya. PSA decided to also take the lead in closing an important part of the food safety gap: implementing a fully compliant potato traceability system.

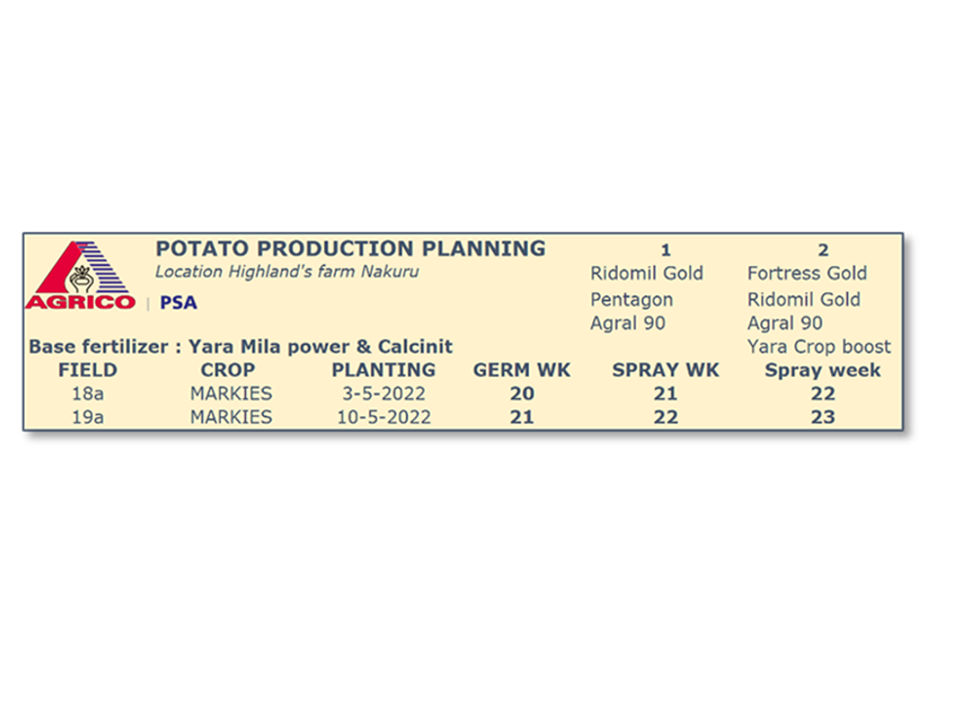

Potatoes where & when grown

The potato traceability system basically provides a rock solid reporting system from which anyone can see where precisely the potato was grown: each field number relates to a geographical area (registered on a field map). Moreover it also shows when it was planted and when the crop germinated.

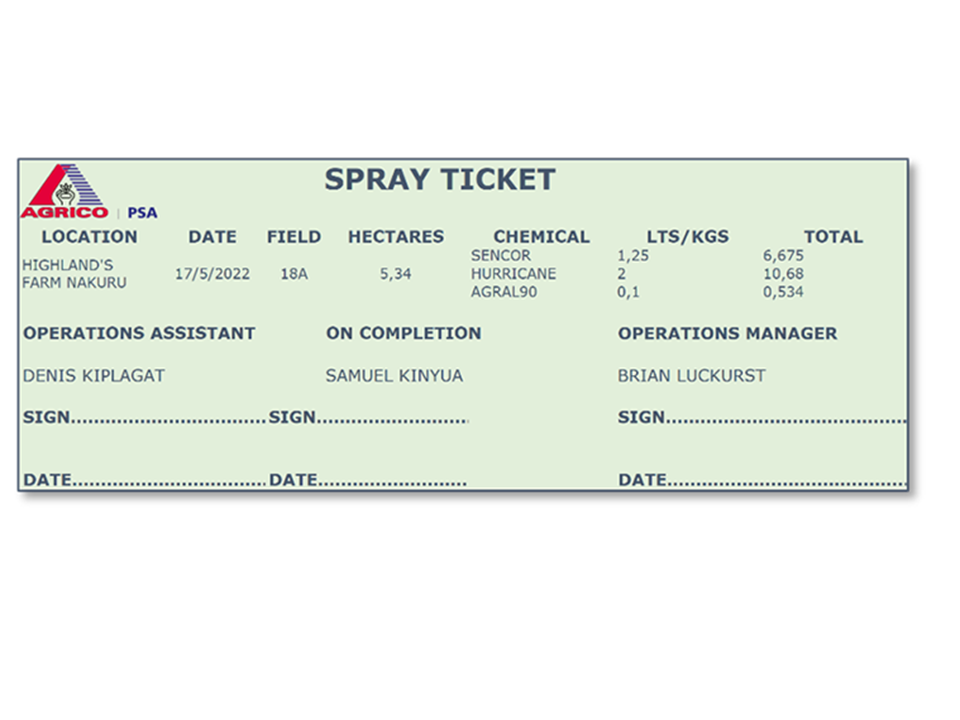

Crop protection & crop nutrition : how much used

Next to having a clear reporting of the crop nutrition and the crop protection products used, it is also mandatory to report how much has been used. For this spray tickets are issued, clearly instructing the operators how much of what material is to be used on what location and when. At the end of the day, the spraying work is checked in the field and frequent overall cross checks by the operations manager are also applicable. This highly planned approach is also a key pillar of intensive agricultural practices. As a result yields are optimised, maximum benefit from applied crop protection and nutrient products is realised and potato farming profits are increased.

What crop protection & crop nutrition products used

But it is much more than that: it provides a detailed reporting of all the crop nutrition and crop protection materials used. Potato is a high value crop and it requires intensive management. This week to week reporting of used input materials thus continues until the moment of harvest. It delivers an integral & precise overview of the crop nutrition and crop protection materials that were used and when exactly.

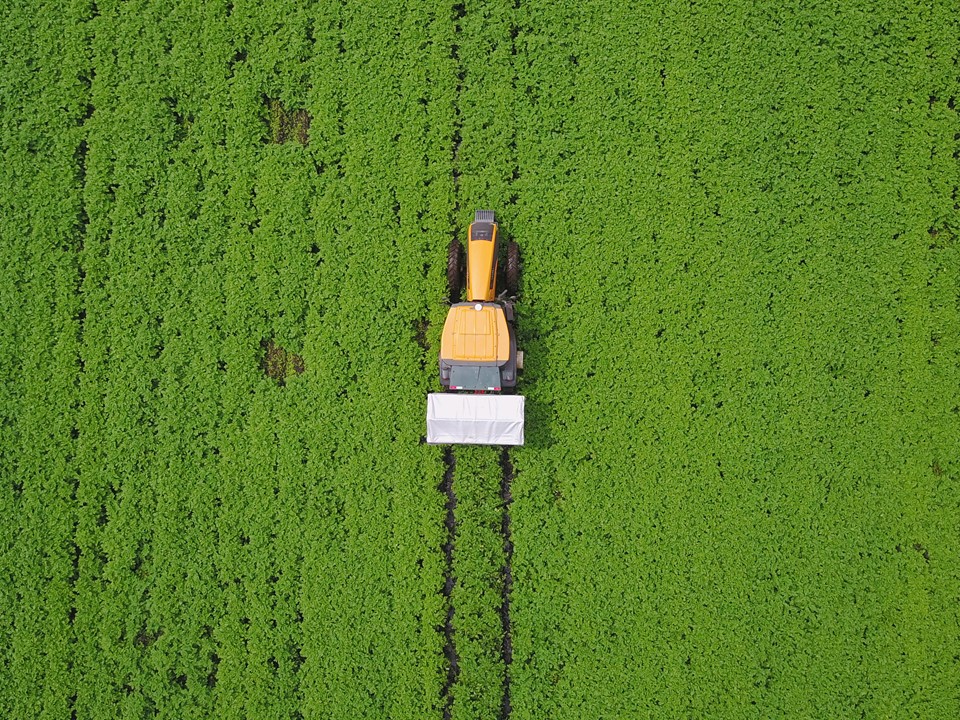

Crop protection application accuracy : equipment calibration

PSA is modern and highly mechanised potato farm, this means state of the art equipment is used for spraying. However from time to time farming equipment can become less accurate. Regardless if our staff pick the right materials and use them in the right quantities, the farming equipment can spray more or sometimes less crop protection products than needed. In order to assure the equipment actually sprays what is required, frequent calibration of the equipment takes place. If needed, spare parts are replaced to ensure all equipment is performing in the right manner. The results of frequent calibration checks are reported in a separate calibration report.

Checks & balances | official and safe products only

All the reports mentioned earlier are stored both digitally as well as physically. Next to that PSA also keep records of the purchase orders, invoices and delivery notes of all the materials used. All materials are only purchased from official distributors of crop protection & crop nutrition means. This means PSA is certain it is supplied with the official safe and accredited input materials and it has no risk of using counterfeit, illegal and / or toxic products. Off-takers and their customers are ensured the potatoes are produced according to the highest food safety standards. Frequent inventory checks are performed by PSA’s financial department. This ‘checks and balances’ system is to make sure what we report in our production unit is also confirmed by our financial department.

Naturally PSA also has all the importation documents of the basic seed from the Netherlands and all KEPHIS seed certificates. In other words: a complete paper trail is available from imported basic seed, used crop nutrition, crop protection, various reports etc. for each produced Kenyan potato. Upon request the reports can be shared with its customers, for instance in case it is required by modern retailers (for instance for audit purposes).

Ready to supply high demanding modern retailers

This combined management system - production planning, record keeping, equipment calibration, use of certified seed potato, official input material and check & balances - resulted in PSA being the first company in Kenya to have a fully compliant potato traceability system deployed. Potato off-takers (processors, packing companies etc.) who buy their potatoes from PSA are assured they comply to the tight traceability requirements from high demanding modern retailers. Potentially it can also unlock export markets for them.

Naturally Kenyan farmers also benefit: we encourage them to implement our traceability system themselves. Combined with growing our certified seed potato varieties – for instance Markies – they too can become “key players in this premier potato league”!